CEAD’s Robot extruders as technology components

CEAD offers its robot extruders as complete standalone systems, accompanied with a base unit that controls temperature, extrusion speed, automatic material transport and which ensures safe operations. This means it includes everything needed for extrusion of thermoplastic materials and start your additive manufacturing process. The extruders are regularly integrated with robot-arms and gantry-based solutions. The robot extruders are ideal to turn your existing robot- or CNC system in a large scale 3D printer.

The extruders are designed to process fiber-filled thermoplastic pellets, a cost-effective material that offers high performance and quality. The extruders process virtually all short-fiber reinforced thermoplastic composites, making them widely applicable to many industries. We offer ancillary systems that help to maximize your workflow, such as a pellet dryer and a proprietary print bed.

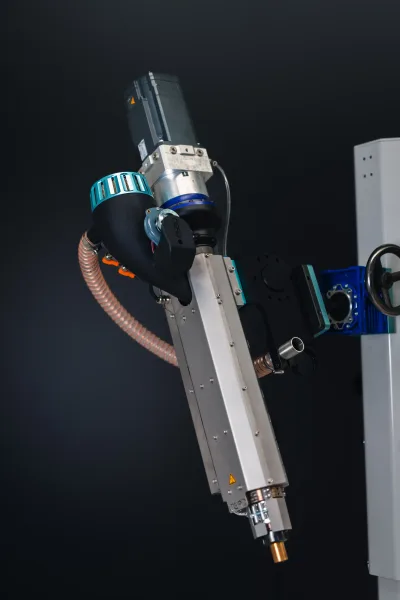

E25 Robot Extruder

Lightweight Pellet Extruder

The lightweight E25 extruder can operate as a standalone system. Due to its light weight and high output it offers an cost-effective and reliable turnkey system that can be integrated onto a wide variety of robotic arms or CNC machines. The system is accompanied with a base unit that controls temperature, extrusion speed, automatic material transport and which ensures safe operations.

S25 Robot Extruder

Lightweight high output pellet extruder

The lightweight high output S25 extruder can operate as a standalone system. It has the same screw diameter as the E25 model, but offers more material output for higher production demands or larger parts. The extruder can be integrated onto a wide variety of robotic arms or CNC gantry machines. The system is accompanied with a base unit that controls temperature, extrusion speed, automatic material transport and which ensures safe operations.

E40 Robot Extruder

High Output Pellet Extruder

High output pellet extruder The E40 extruder is our optimized weight to high output extruder. It is especially suitable for the production of large parts, when production demands are high or when interested in large bead additive manufacturing. The extruder can be integrated onto a wide variety of robotic arms or CNC gantry machines. The system is accompanied with a base unit that controls temperature, extrusion speed, automatic material transport and which ensures safe operations. In combination with the Flexbot, it ensures high output and maximum flexibility and accuracy.

E50 Robot Extruder

High Output Pellet Extruder

The E50 extruder currently has the highest output in the CEAD extruder portfolio. The maximum output in combination with large nozzle sizes enable large bead manufacturing and production or large parts. The extruder can be integrated onto a wide variety of robotic arms or CNC gantry machines. In combination with the Flexbot with large print bed area (e.g. Flexbot Industry or Flexbot Custom), it maximizes the workflow of the system.

Print beds

Stable & accurate building platform

Proprietary print beds are produced by CEAD to provide a rigid, stable and easy to use building platform. The print bed uses aluminum profiles (hook – picture) to mechanically secure your print to the print bed surface.

During printing, these profiles create a non permanent mechanical bond between the bed and the printed object. The lever on the side of the print bed will break this mechanical bond releasing the printed object. This feature is unique in its kind and was firstly introduced by CEAD and is up till now the only provider of such a solution.

The print bed can be upgraded with the heated bed function. This upgrade gives you a print surface of up to 100 ° C (212 ° F), which works great for materials that require more gradual cooling.

Pellet Extruders

Light weight & Easy to mount

The extruder is engineered to be lightweight for the sole purpose of mounting it on a robotic arm. While several different types of robotic arms are available on the market today, we aim to be able to install the extruder on most types, weighing in at a little under 29 kilograms.

Multi materials

The extruder is able to use a wide variety of materials ranging from PP to PPS filled with carbon or glass fibres. A steady flow of plastic pellets to the barrel is achieved by blowing air from the 25kg container through a maximum of 20 meters transportation hose, in to the inlet located at the top of the extruder assembly.

High production output and low cost

Using pellets materials for 3D printing is cheaper than using filaments reducing operational and part cost. Another benefit of using pellets for 3D printing is the higher outputs than filament based machines. Depending on the material this extruder can reach outputs of up to 12kg/hr

High Torque stable control system

With an Siemens servo motor as a drive system we obtain maximum stability and reliability. Extremely high torques are readily available because of the implemenation of a 20:1 planetary gearbox. The combination of a servo motor and a planetary gearbox make the drive system the best performance possible.

Easy to Swap nozzle

The nozzle is located at the very end of the extruder barrel. The lowered complexity for the geometry of the nozzle allows for a variety of types to be installed. Nozzle sizes can range from 2mm up to 12mm depending on your application.

Stand alone

The whole system is operated through a Siemens touchscreen, which runs our specifically designed software. This software is the result of years of experience in plastics extrusion, 3D printing, and machinery development. When needed the extruder can be operated as a stand alone unit. It is also possible to connect this system to your robot or machine. This gives your robot the control over the extruder.

Compatibility

The extruder can be connected to virtually any robot controller. We can supply multiple connection methods, including: Profinet, Profibus, Fieldbus or digital I/O. All components inside the extruder and cabinet are controlled by an industry standard PLC (Siemens). Let us know if you need help with connecting your robot to our extruder or if you have special request. Our software engineers can help and advice you in any situation.

Specifications E25

| Weight extruder | < 29kg / 64lbs |

| Total height | 920mm / 34” |

| Width | 230mm / 9” |

| Depth | 340mm / 13.5” |

| Screw diameter | 25mm / 0.98” |

| Compression ratio | 1:3 |

| Mounting on robot | Aluminium mount |

| Nozzle-bracket dist. | 435mm / 7.1” |

| Heat zones | 4 |

| Cooling zone | 1 (material inlet) |

| Heat control | Siemens PID |

| Cooling | Water cooled |

| Control system | Siemens S7-1200 |

| Human machine interface | Siemens KTP-700 |

| Software | CEAD custom |

| Power Servo motor | 0.75 kw |

| Drive system | Siemens servo motor |

| Heating power | 1,7kw |

| Extruder control | RPM, servo motor |

| RPM control | Internal controllable by HMI or Externally with 0-10v or 4-20ma or externally connected to your robot / system |

| Material transport | Integrated |

| Material storage | > 25kg / > 55lbs |

| Material transport max. distance | 20 meter (10 meter is standard) |

| Material transport control system | Automatic by CEAD custom software |

Software

Extruder temperatures

All different heating zones are controllable through the touchscreen. Motor and screw RPM are also shown. The extruder includes several safety features for reliable and safe operation.

Complete control

In the settings menu the user has control over the system. Limits can be programmed as well as controlling both funnel temperature and material transport.

Recipes, storing different settings

Printing with a variety of materials, locations and weather conditions, involve different settings for different materials. So called ‘Recipes’ are saveable presets of settings for the system. This allows for a quick set up when starting the machine with a known material. All recipes can be both exported and imported through USB connection ports which allows for easy sharing.

Logging of the process

A variety of sensors keep track of the temperatures along the different heating zones during set intervals. The extruder speed set point and realtime speed are monitored as well. All this information will be displayed real time and consequently logged to storage. The operator can save the logged files on a usb stick. This allows for quality control, troubleshooting, optimization and streamlining the process.

Materials

We are constantely trying to proces new materials on this extruder. With the high temperature and high torque design we can virtually process all available materials. This is a list of tested materials, contact us if you would like to test your material on our system.

| Material | Filler material |

|---|---|

| ABS Thermocomp ac004xxar1 | 20% Carbon fiber |

| ABS Thermocomp af004xxar1 | 20% Glass fiber |

| Arnite (PET) | 50% Glass fiber |

| Nylon PA6 | 10% Carbon fiber |

| PE | – |

| PET-G | – |

| PET | 30% Glass fiber |

| PESU, electrafill 1810 | Carbon fiber |

| PP | 30% Glass fiber |

| PP | 50% Glass fiber |

| PPS | 30% Carbon fiber |

| PEEK | 30% Carbon fiber |

Material test PESU 1810 carbon fibre

Complete robot solutions

CEAD is a developer of large-scale 3D printers and equipment. We have developed and build large-scale composite pellet 3D printers based on gantry style machines and on robots. An example is the combination of 3D printing and 5 axis cnc machining for the production of tooling and moulds. We are happy to help and advice you with the right system for your application. Choose one of the solutions below for more information or contact us directly.

Contact

Fill in the contact form in order to discuss the options and possibilities or download the robot extruder brochure.